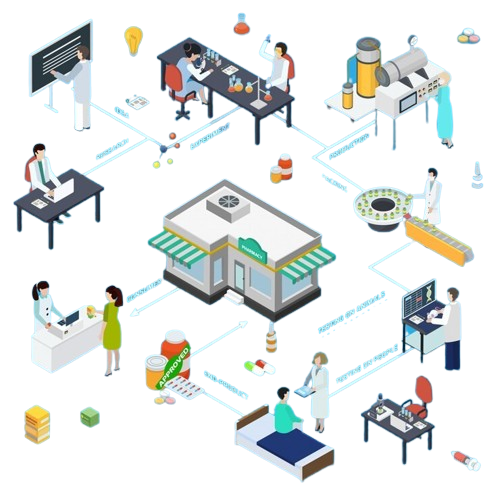

Third Party Manufacturing In Pharma

Outsourcing of pharmaceuticals, also called Third Party Pharma Manufacturing is a common practice in the sector. In this arrangement, a drug manufacturer (client) outsources its product production to another company (manufacturer) that has the relevant infrastructure and skilled personnel. This model has gained traction because among other things, it has several advantages and enhances efficiency in the process of manufacture.

Moreover, third party manufacturing not only helps in terms of efficiency but also quality. These manufacturers follow strict quality control measures and adhere to international standards so that the drugs they produce are safe, effective and of high quality